Image: Alchemy Bicycles.

By Veronica Penney

Not all bikes are created equal. Alchemy Bicycles, a Denver-based handmade bicycle manufacturer, has discovered the formula to produce some of the highest quality bike frames in the industry.

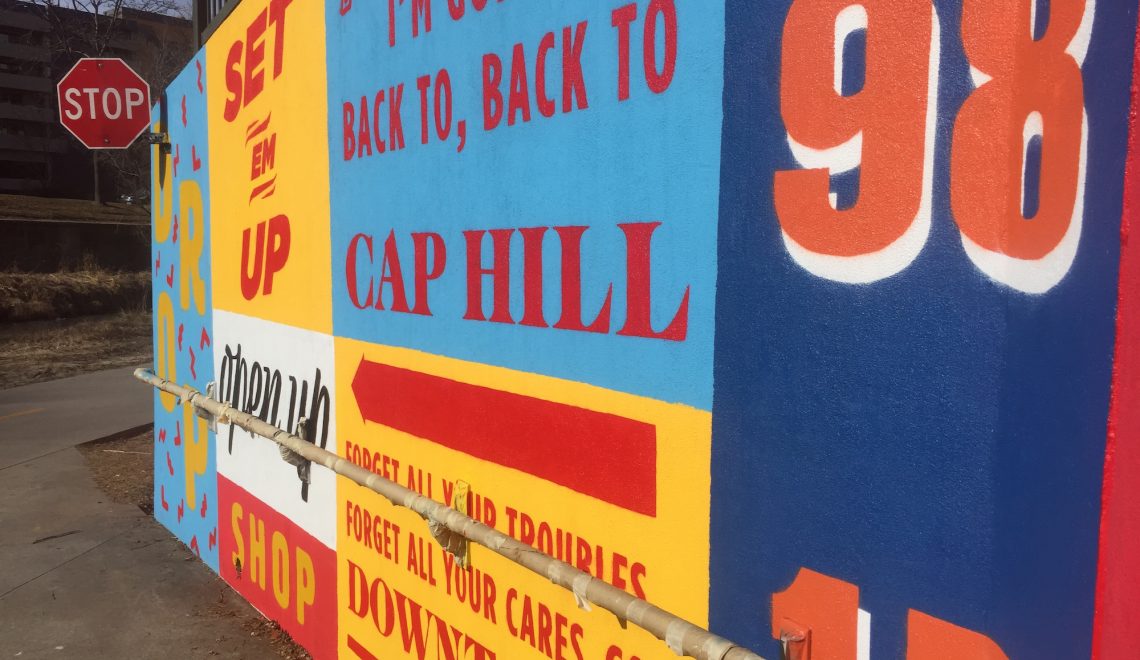

Alchemy started in Austin, Texas back in 2008, and relocated to the Cherry Creek neighborhood of Denver in 2012. A number of factors made Colorado a good fit, including the thriving bike scene, an abundance of local talent, and great ride routes. The ability to pull talent from other states to a Colorado location didn’t hurt, either.

“Attracting talent to Denver? Way easier than attracting talent to Texas. As soon as we started talking about Colorado, everybody was interested,” says Megan Cannizzaro, one of Alchemy’s founders.

Over the years, Alchemy has built a name for themselves in titanium, steel, and carbon handmade bikes. Falling somewhere between the small handmade manufacturers, who might produce only a handful of bikes per month, and larger manufacturers that churn out thousands of carbon frames, Alchemy is unique in the sophistication of its operations for its size.

Photo: Alchemy Bicycles

In a rapidly-evolving industry like cycling, constant innovation is essential to success. By keeping all manufacturing in Denver, Alchemy has quick turnaround time on new product designs, which translates to a streamlined product development process, from design through distribution.

“We do everything in house, from design, all the way to completion,” explains Cody Baker, Alchemy’s Sales Manager. “We’re one of the only bike companies in the U.S. who actually manufactures their own carbon fiber tubing. For us, it’s all about quality control and keeping the product at a higher level, all the way from beginning to end.”

Like many other bike manufacturers, Alchemy starts designing their carbon bikes by creating a model in a 3D CAD program. The CAD design is programmed into a CNC machine, which cuts molds out of aluminum blocks.

Where Alchemy’s carbon bikes start to differ is in the assembly process.

“What we do is tube to tube construction, which is similar to a metal frame,” says Baker. “You’re actually mitering the shape out of one tube to join it to another, and then we’re hand wrapping the joints. You can really play with how the bike rides and the end result just by the way that you wrap up each of those junctions.”

Photo: Alchemy Bicycles

“As far as the welding and the metal, a lot of it comes down to the quality of the metal. The steel and titanium that we use are very high quality,” says Lindsey Reese, Alchemy’s Marketing Coordinator. “Our welder is an artist when it comes to putting the tubes together. Those junctures do a really good job of absorbing the pressure and the chatter, and just making a smoother ride.”

In addition to their production models, Alchemy offers custom built bikes, which is where that ability to fine tune the bike’s ride qualities is key.

“We really want to focus on the customer’s satisfaction level, so we do put people on a fit bike and we get their size, their geometry, how they pedal, and all that goes into the idea of building their bike,” explains Reese. “Those are aspects of the company that set us apart from smaller companies that do custom bikes or do one-off bikes: we really focus on the individual customer ride performance.”

“I always say these are the bikes you’re gonna grow old and die with, so you want to make sure you don’t have any pressure points or pain points when you’re riding that bike.”